It is important to monitor performance in production lines in all types of businesses

Why is it important to monitor performance in Automatic Assembly Line, you might wonder? The main argument is simple – you can’t improve what you don’t measure. If you don’t have measurements or data telling you how your production is performing, it is hard to make improvements that can make your production equipment more efficient. The monitoring of a production line’s performance is relevant in all types of businesses, but mainly in the businesses where the margins are tight. In, for example, the food packaging business, where the margins are razor thin, a small increase in effectiveness can make a big difference to your bottom line.

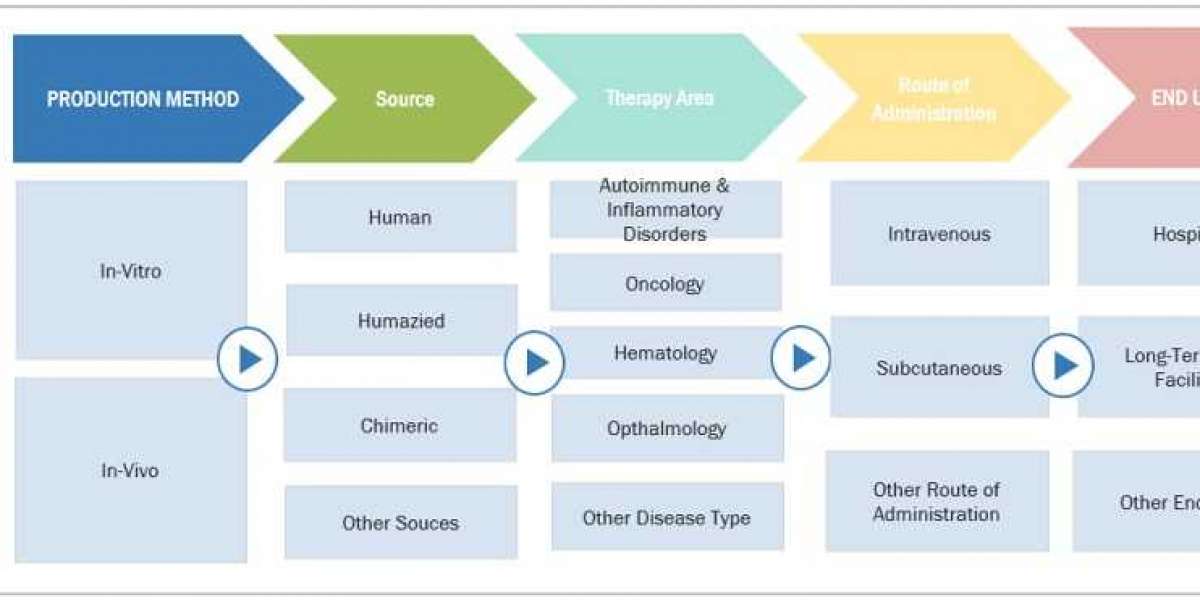

Adapt your monitoring method according to your business and needs

Depending on factory and business, there are several ways to monitor the performance of a production line. In theory, the simplest way is to use pen and paper and have someone watching the production line, using a stopwatch. In reality, if you have a complex factory with many machines, this solution is not realistic for anything but a short-term test. Instead, a more suitable and also a more common solution, is to use a software-based solution. A software program delivers useful and detailed information on how your production line is doing and where there is room for improvements. The more accurate measuring method, the better your adaptions will be to improve your production line’s performance.

If you have interests about alternator assembly line, welcome to send us messages.