Top needles are critical for making parts. They are an integral part of the mold ejection system, which determines the final result of the product during the injection molding process.

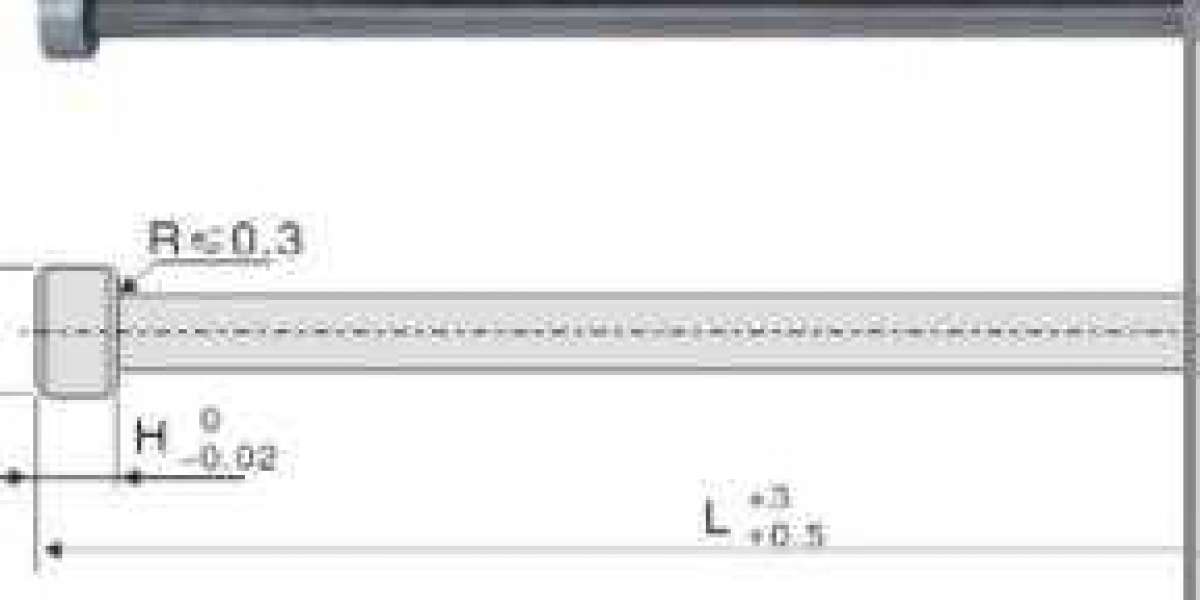

There are many types of thimbles used in the manufacture of products. Such as straight ejector pin, sling ejector pin, shoulder ejector pin, etc. Let's take a look at the specific categories.

Hard thimble

These thimbles are heat treated to ensure consistent hardness across the diameter of the thimble. Through hard pins can withstand operating temperatures up to 200°C and are best suited for plastic ejection systems in molds.

Case hardened thimble

Also known as Nitride H13 pins, they are harder than straight-through hard pins and are suitable for die casting ejector systems in molds. Case hardened pins are nitrided to 65 – 70 HRC and can withstand temperatures above 200°C.

Black thimble

Since Nitride H13 thimbles cannot be used at operating temperatures above 600°C, the manufacturer developed these thimbles. Black thimbles are painted with a black finish, are self-lubricating, and withstand high temperatures up to 1000°C. It is an expensive ejector pin for metal ejection systems in automotive molds.

Taizhou Huangyan Jinhong Plastic Mould Parts Co., Ltd. is an injection mold maker from China, The company sells straight ejector pins, mold parts, and other related products. The company can provide special products.