In the growing construction markets of Latin America, demand for efficient and reliable concrete production is on the rise. While there are many standard concrete plants available at competitive prices, a noticeable trend has emerged—more and more contractors are choosing customized solutions despite the higher upfront cost. On the surface, it may seem counterintuitive to opt for a more expensive option. But a closer look reveals why tailored concrete plants are gaining popularity across the region.

From geographic challenges to varied construction needs, Latin American contractors often face complex conditions that standard plants simply cannot meet. This article explores why a customized concrete plant for sale(venta de planta de concreto) is often the better long-term investment, and what makes it so appealing to the region's builders.

Unique Regional Challenges Require Tailored Solutions

Adapting to Diverse Environments

Latin America is a region marked by extreme geographic and climate diversity. Construction may take place in humid rainforests, mountainous terrains, coastal cities, or arid highlands. Standard concrete plants are often designed for general conditions, which can lead to performance issues when deployed in harsh or non-ideal environments.

Customized plants, on the other hand, are engineered to handle site-specific challenges. For example, in high-altitude locations, the plant’s control systems may need to be adapted to air pressure changes. In coastal regions, anti-corrosion coatings and salt-resistant components are essential. These environment-specific adjustments significantly improve reliability, making the investment in customization worthwhile.

Flexibility in Installation and Mobility

Many construction projects in Latin America are carried out in phases or involve multiple remote sites. Customized concrete plants can be designed with modular or mobile features, allowing faster relocation and easier installation. This is particularly important in areas where infrastructure is limited or where access is restricted.

A tailored layout can also reduce the need for large foundations or complex assembly, cutting down installation time and related costs. These mobility advantages help contractors stay on schedule and adapt quickly to new project requirements.

Customization Improves Efficiency and Reduces Waste

Precision Material Control

One of the key benefits of a customized concrete plant(planta de hormigón Perú) is the ability to fine-tune material feeding and mixing systems to match specific mix designs. For example, projects that require high-strength concrete or special additives benefit from customized dosing systems and intelligent weighing solutions. This level of control reduces raw material waste and improves overall mix consistency—both of which have a direct impact on project profitability.

Latin American contractors often face tight budgets and volatile material prices. Customized systems that help reduce consumption by just 5–10% can translate into substantial cost savings over the course of a project.

Advanced Automation and Smart Features

Many standard plants come with basic manual controls. However, custom concrete plants frequently include advanced PLC systems, one-button start-up, remote monitoring, and diagnostic dashboards. These features allow fewer operators to manage production with greater precision and fewer errors.

Contractors appreciate the reduction in labor dependency and the increased transparency into plant performance. For regions with limited access to skilled labor, automation is not just a bonus—it’s a necessity.

Long-Term Value Outweighs the Initial Cost

Durability and Component Longevity

Customized plants are usually built with higher-quality materials and reinforced components tailored to local conditions. Whether it’s enhanced wear resistance in high-dust environments or reinforced chassis for transport on rough roads, these improvements extend the plant’s lifecycle.

While the initial price tag of a concrete plant for sale may be higher, the reduced need for repairs and replacements means fewer disruptions and lower long-term maintenance costs. This leads to a faster return on investment, especially for contractors working on continuous or long-term projects.

Scalability and Future-Proofing

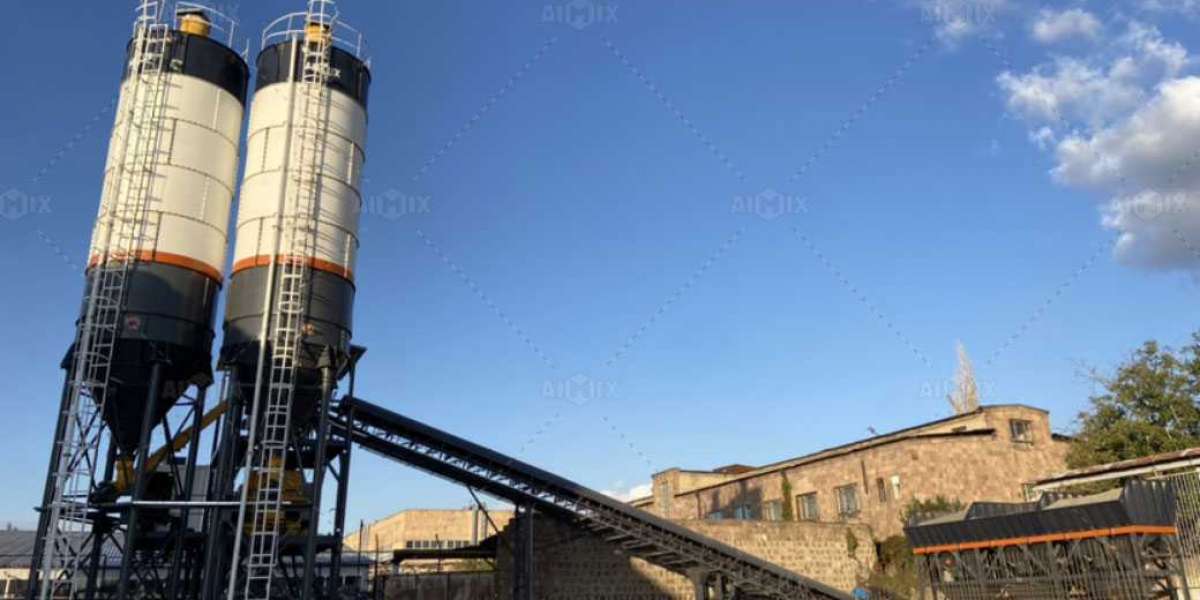

A standard plant may be limited in its ability to evolve with a growing business. Customized concrete plants(plantas de concreto en Chile) can be designed with future expansion in mind—such as extra silos, modular mixer upgrades, or additional aggregate bins. This flexibility allows contractors to scale their production without replacing the entire system.

For companies in Latin America looking to grow their operations or serve more complex projects, this scalability is a compelling reason to invest in tailored solutions from the start.

Conclusion

The rising popularity of customized concrete plants in Latin America is not just a matter of preference—it’s a response to real-world demands. From environmental adaptability to operational efficiency, the benefits of customization address the unique challenges faced by contractors across the region.

While the upfront cost of a customized concrete plant for sale is undeniably higher, the advantages in productivity, reliability, and long-term cost savings make it a smart and strategic investment. For construction companies aiming to stay competitive in a rapidly evolving market, customization isn’t a luxury—it’s a necessity.