Using plastic injection Mold parts, only the exact amounts of plastic are used to create and shape the final product as it involves injecting the plastic into an exacting mould. It has been proposed that if there is any excess in channels, it can be ground again, melted, and used to make a new moulding. Since a mould tool might be used to create hundreds or thousands of products, the entire production process produces little-to-no waste, which represents a significant amount of waste reduction.

Wood and metal can be used to produce similar products, but these materials require much more waste and each item will take longer to produce, especially the more complicated shapes; things that could be formed using a single piece of plastic may need multiple pieces, which would increase production costs.

Furthermore, natural materials tend to decompose over time and are harder to clean. Although this may be suitable for some products, for items that will be in regular use for a long time it doesn’t seem feasible to produce five different plastic items to match the life of one made from natural materials.

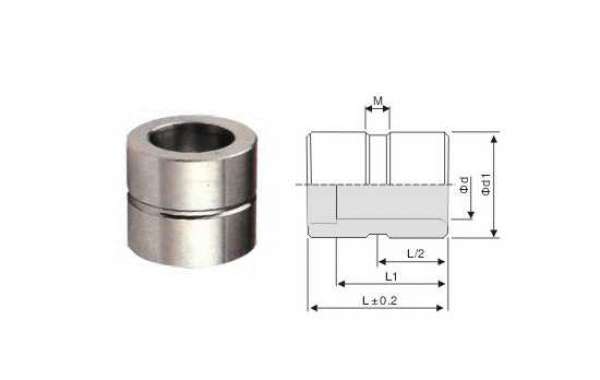

We are one of the Guide bush supplier and welcome your consult!